Welcome to Hefei Trancar Industries Co.,Ltd.

Welcome to Hefei Trancar Industries Co.,Ltd.

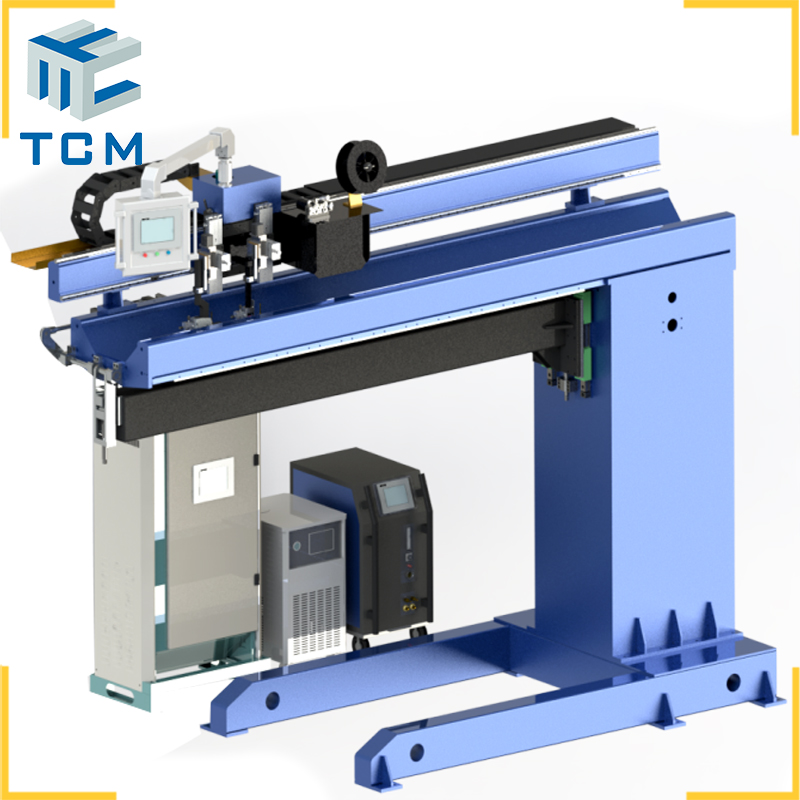

Steel tank body cylinder shell longitudinal seam welding machine from Trancar Industries China

Steel tank cylinder shell Longitudinal Seam TIG Welding Machine

1 host machine

Standard welding machine mainly composed of main frame, key press type pneumatic fixture, welding core shaft, shaft bracket, gun running mechanism, lifting mechanism, the torch of pneumatic mechanism, a welding torch adjusting mechanism and pneumatic control system and other components.

1.1 Main frame

The main frame adopts frame type welded structure, with enough rigidity and strength, to meet the long-term use of the stability of the equipment. Base can be fixed by foundation bolt, to ensure the stability when welding. There is a small door at the side of the cabinet of the main frame; side door is installed with air source treatment unit, solenoid valve, pneumatic control components and electrical wiring terminal devices.

1.2 Key type pneumatic fixture

This piano type pneumatic fixture is designed for longitudinal seam and unique design of welding, pressing the keys with special pressure mechanism, the keys press finger has forward force on the work piece, can eliminate the longitudinal joint assembly clearance automatically.

Key type pneumatic fixture consists of beam, air float etc. Beam is steel welded structure, bilateral symmetry, with enough stiffness and strength, ensure no deformation during using. The distance between left and right keys can be adjusted in the range of 5 ~ 30mm, in order to suitable for different welding seam width for different thickness of work piece.The front end of the keyboard plate copper pressure is consumable parts, if it is burning during welding, and can not press the work piece tightly and radiation protection effect decrease. Please replaced or repaired the damaged copper pressure frequently, otherwise it will affect the welding quality.

Longitudinal Seam TIG Welding Machine main parameter:

Pipe effective welding length | 1500mm/2000mm |

Clamping max. length | 1500mm / 2000mm |

Clamping max. dia. (outer side welding) | Φ300mm |

Clamping min. dia.( inner side welding) | Φ1500mm |

Clamping Min thickness(outside weld) | 1.0mm |

Clamping Max thickness(outside weld) | 3.0mm |

Walking velocity | 110~1100mm/min |

Contact us for more TIG welding solution: